Решение автоматической упаковки рулонной холоднокатаной стали – непростая задача, требующая совместной работы нескольких отраслей. Поскольку процесс упаковки включает в себя обработку стальных рулонов, упаковку рулонов с различными упаковочными материалами, бумажное покрытие и обвязку рулонов ...

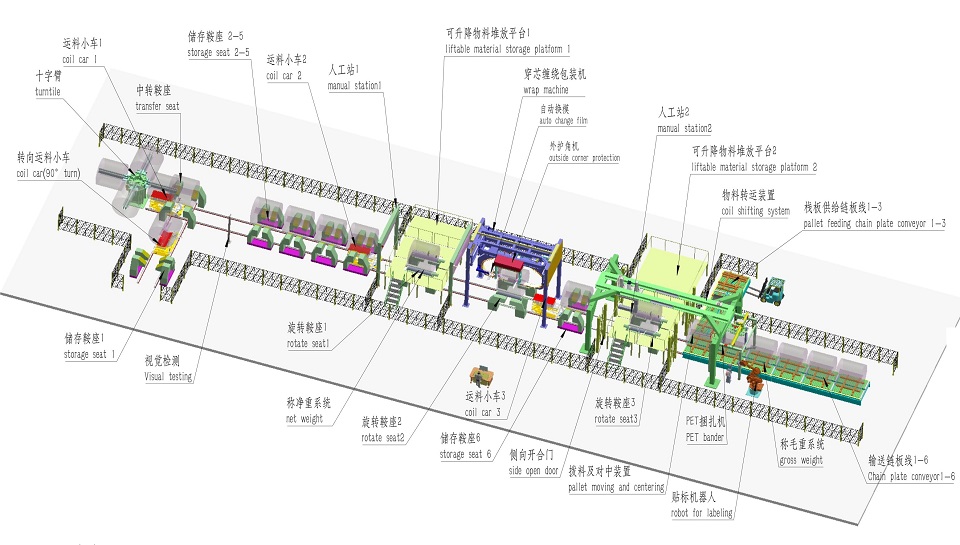

The solution of the cold roll steel coil automatic packing is not a easy job which needs several industry working together. Because of the packing procession includes the steel coil handling, coil wrapping with different packing material, paper covering and coil strapping …

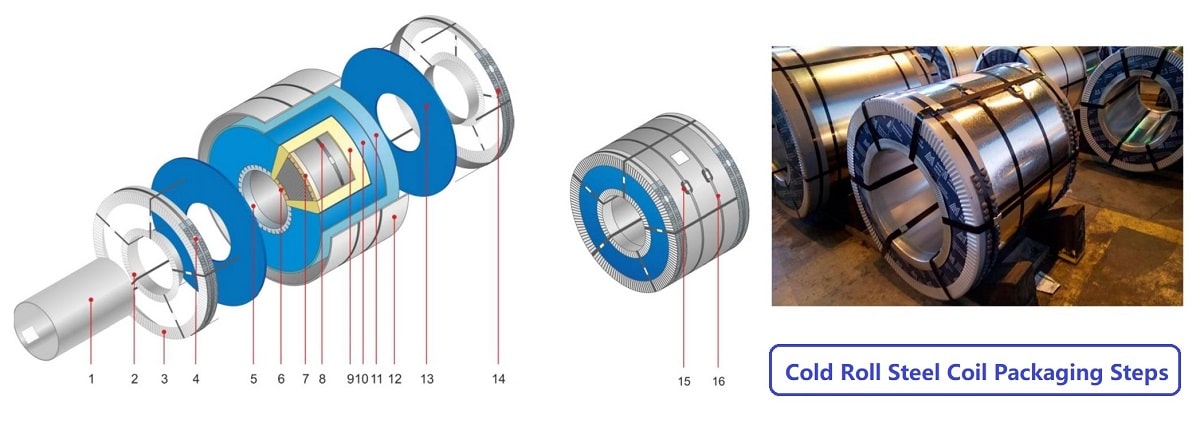

Ниже приведены общие этапы упаковки рулонов холодного проката и обращения с ними.

Following is the general packing steps in the cold roll coil packing and handling.

Above photos includes the following packaging procession. It is the standard packaging way for many manufacturer in target of the sea worth transportation.

- ID hole protector

- ID steel edge protector

- OD steel edge protector

- OD edge protector strapping

- ID cardboard protector

- OD cardboard protector

- Cold roll steel coil OD strapping

- VCI paper covering

- VCI film stretch wrapping

- Cardboard OD covering

- Steel sheet OD covering

- Side cover

- OD Edge protector

- Cercumferece coil strapping

- Radial coil strapping

The Major part of the cold roll coil packing line in the automation is wrapping and strapping.

a. wrapping

The packing material can be stretch film, VCI paper, VCI film…

B. The strapping solution hand radicial and OD strapping

For the OD strapping: The strapping head adjusting the position for OD strapping.

Steel Coil Handling

- Coils can weigh several tons, requiring robust gripper mechanisms, lifters and conveyors to transport and position them efficiently.

- Secure clamps or vacuum cups are needed to hold the coils during the packing process without distortion.

Coil Wrapping

- Wrapping machines must apply layers of stretch film, foam, cardboard sheets and end protectors precisely to conform tightly to the coil geometry.

- Adjustable wrapping mandrels and frame dimensions are necessary to accommodate different sized coils.

- High tension control of the wrapping material is critical to achieve a durable yet flexible containment.

Paper Covering

- Paper rolling machines can apply 1-2 layers of kraft paper or abrasion-resistant film around the base of the coil to protect surfaces during transport and storage.

- The paper unroll mechanisms must synchronize with the coil rotation to achieve an even wrap.

- Adhesive is typically applied to bond the paper to the underlying layer(s) and seal any edges.

Coil Strapping

- Automatic strapping heads radially apply 1-4 overlapping bands around the outside diameter of the packed coils using steel or polyester straps.

- Controllable tension mechanisms need to apply the optimal securement forces for different sized coils.

- Sealing systems bond the strap ends to prevent loosening during handling and vibration.

Overall, developing an effective automated packing solution for cold rolled steel coils requires integrating subsystems across material handling, wrapping, covering and strapping – designed and optimized as a unified system accounting for the heavy weights, large dimensions and wide range of coil sizes involved.

More information: https://www.fhopepack.com/Automatic_Coil_packing_machinery.html

info@fhopepack.com