High speed tyre wrapping machine and packing machine supplier.

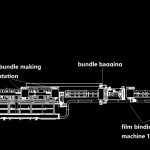

The machine includes following device:

- 1. press down device

- 2. tapping device

- 3. PLC

- 4. ring reset

- 5. overload protecting

- …

http://www.fhopepack.com/Tyre_packing_machine.html

The machine can do wrap for rim packing, cycle tyre wrapping, Car tyre packing…

Easy operation and friendly for non skilled operator.

High speed: 15-25 sec per tyre

- These machines are used for rapidly wrapping and packing vehicle tires. They provide an efficient and automated solution for tire manufacturers, retailers, and distribution centers to package large volumes of tires.

- High speed tire wrapping machines use stretch polypropylene film to wrap tires individually or bundle multiple tires together. They can wrap up to 100-200 tires per minute depending on the model. Bundlingreduces space requirementand prevents tire damage during storage and shipping.

- Key features to consider include maximum wrapping speed, maximum number of tires that can be bundled, film width supported, film unwind and rewind mechanism, control panel, safety features, etc. Wider film width can handle larger tire sizes. Higher speeds and greater bundling capacity mean higher productivity and output.

- Tire wrapping film is durable, stretchy, UV resistant polypropylene. It prevents damage, corrosion and moisture absorption while still allowing easy unpacking of tires. Perforated or tear-off end provides easy access to wrapped tires.

- Tire packing machines then pack the wrapped tires onto wooden, plastic or paper pallets for palletized shipment. They use slip sheetsunder tires and secure the pallets with stretch hood film, straps or steel bands. Pallets can hold 100-500 tires depending on size.

- Benefits include reduced manual labor, consistent and secure packing, prevention of damage and product loss, efficient storage and transportation, automated record-keeping,customizable bundling for retail sale, and space savingsfor warehouse storage.

- Applications include tire manufacturing plants, tire retailers, auto parts suppliers, vehicle service centers, military bases, etc. These machines meet the high-volume packaging needs of these industries.

- These machines require installation on even floor surfaces in dry, dust-free environments. Proper space, electrical connections and access to packaging supplies is also needed. They offer an economical but productive solution for packing large quantities of tires.