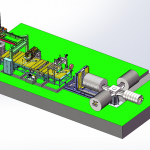

COIL PACKAGING LINES

Automatic coil packaging machine lines are designed for connecting with the slitting line to handling the coil that is lower the labor intension and improve the coil handling speed. Equipment can be designed especially for your needs in coil size, layout direction and automation Iot system. Regular the designs vary from packaging goals in manual or semiautomatic. And the auto strapping machine in an option of the machine.

For integrated coil packing system with the slitter line, there is need a transfer coil car and track.

Coil car- For moving the slitted coil from winding roller to the turnstil that is able up and down adjustment for height.

Turnstile – There are several version in two, three or four arms that is for storage the coils for buffering.

Downenders – it is an important device for picking up the coil, the downender is able checking and moving the single coil from turnstile and 90 degree ending to the conveyor totally automatic.

Strapping Machines – strapping heads can be programmed for full automatic operation with turning table for 3/4/6 belt strapping. .

Coil Stacker – Picks the stacking coils. It OD pick up the coil from conveyor and move to the stacking position. The stacking device can be fork arm, magnet, vacuum…

Turntable – for turning stacked coil on pallet and displace to the conveyor per setting that is 6 or 8 positions.

Pallet Strapping – For automatic coil strapping together with pallet.

More coil packing line solution: https://www.fhopepack.com/Automatic_Coil_packing_machinery.html