The horizontal wrapping machine is made by the machinetech to produce the highest quality setting which accords with the international quality standard, and is observed by our experienced professionals.

The packer is designed for a straight object. It has achieved successful results in specialties, pipes, plates and other industries. Flat knitting machine is used for steel pipe packaging, aluminum profile packaging, door and window packaging, bar packaging, panel packaging and so on.

This is the equipment for your packaging speed and efficiency.

Solution。 Fhope installed on horizontal rail packer is fully designed and manufactured in many manufacturing sites. In the market, the company’s authoritative science is introduced: the knowledge package, the complementarity of the movement, the opportunity management contract to complete the series of adding function superposition, handling, packaging, binding, and the ability to give the final praise options for the speed of the project and the quality of the finished packaging in any way.

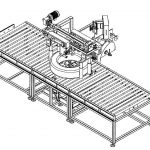

• The automatic machine uses a horizontal design where objects to be wrapped enter horizontally and exit horizontally after being packaged. This maintains a continuous workflow.

• Straight objects like pipes, rods, bars, beams, extrusions, ingots and panels are loaded onto conveyors or a servo table that feed into the wrapping section at a controlled speed.

• A film unwind system supplies stretch film that is precisely tensioned before wrapping the objects. This helps produce a wrinkle-free pack.

• Wrapping is achieved using either a rotating arm or a flat belt system, depending on the machine model. Both allow for partial or full wrapping of the objects.

• PLC controls and servo motors precisely coordinate the movements of the conveyors, film unwind system, wrapping mechanism and film sealers. This ensures a consistent automated wrapping process.

• An HMI touchscreen allows operators to input parameters like product length, film width and wrap count. It also displays production data for monitoring.

• Optional features like inkjet coders, labelling and top sheet dispensers can be included to enhance the packages.

• Fhope works closely with each customer to define their horizontal flow packaging needs and then customize a machine to meet those requirements within the customers’ budget.

• After-sales support includes spare parts, service, maintenance and technical assistance to keep the machines running optimally over their lifespan.